CNC Laser Cutting Services

CNC Laser Cutting Services Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 15 Units Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

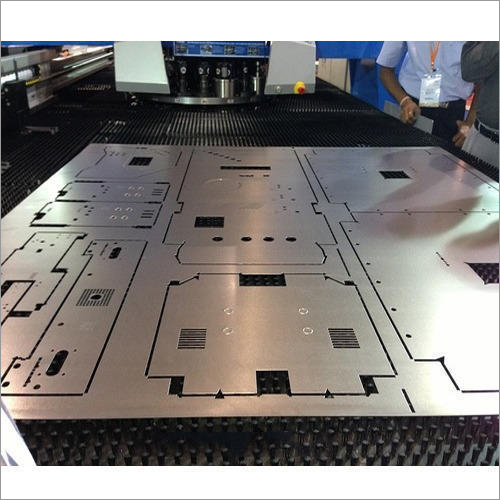

About CNC Laser Cutting Services

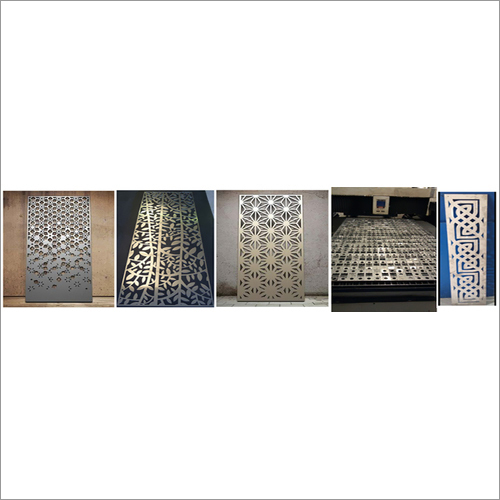

We offer CNC Laser Cutting Services for various industrial sectors in order to design machine components, decorative pieces, automotive parts, & architectural structures. They are provided with help of advanced machines with ability to process bulk workpieces in less amount of time. We are capable of creating all kinds of structures with utmost precision & repeatability so as to gain full client satisfaction. Parts processed by our CNC Laser Cutting Services have negligible burrs with smooth edges. They can be availed for all kinds of metals at cost effective rates and in stipulated period of time.

State-of-the-Art Laser Technology

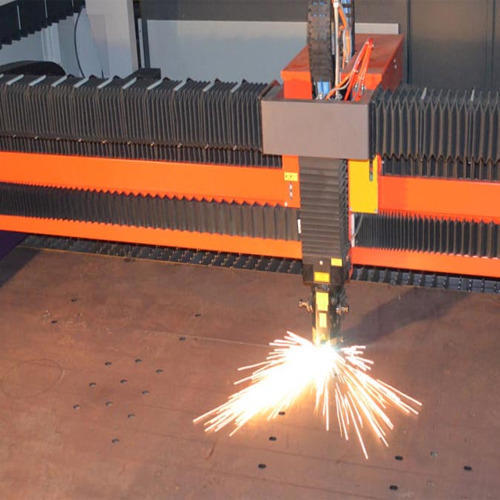

Harnessing cutting-edge Fiber and CO2 lasers, our process guarantees exceptional accuracy with smooth, burr-free edges. Whether for prototypes or mass production, our equipment handles a broad range of materials with optimal speed and consistency.

Flexible Solutions for Diverse Needs

We offer spot-on solutions tailored for industries such as automotive, architecture, and signage. Clients can submit designs in DXF, DWG, or PDF format, enabling seamless integration of their requirements into our workflow for timely, high-quality delivery.

FAQs of CNC Laser Cutting Services:

Q: How does the CNC laser cutting process work for large sheets?

A: Our CNC laser machines handle sheets up to 3000 mm x 1500 mm, using precise computer-guided lasers to cut shapes with high accuracy. The process begins with your digital file (DXF, DWG, or PDF), which is programmed into the machine to perform custom cuts efficiently.Q: What materials and thicknesses can be processed using your laser cutting service?

A: We can process a wide range of sheet materials, including metals and selected non-metals. The maximum thickness for cutting depends on the material type and laser power, but we ensure clean, burr-free edges for all supported materials.Q: When should I choose CNC laser cutting over other cutting methods?

A: Choose CNC laser cutting when you require high precision, intricate designs, and smooth, burr-free edges. Its particularly beneficial for complex shapes, prototypes, and applications demanding minimal finishing work.Q: Where can your laser cutting services be applied?

A: Our services are widely used in industrial manufacturing, architectural projects, automotive part production, signage fabrication, and much more. We cater to varied sectors across India, providing bespoke solutions to match each applications demands.Q: What file formats are accepted for submitting designs?

A: We accept DXF, DWG, and PDF file formats, ensuring compatibility with most design software. This flexibility allows for straightforward transfer of your concepts to our production systems.Q: How does the high-precision, burr-free finish benefit my project?

A: High-precision and burr-free laser cutting minimizes the need for post-processing, enhances the fit and finish of components, and ensures reliable performance in critical applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Laser Cutting Services Category

|

SPAK METAL CRAFTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry